What is Friction Loss in HVAC? It’s a question that often arises when discussing the efficiency and performance of heating, ventilation, and air conditioning systems. Friction loss refers to the resistance air or fluids encounter as they flow through ducts, pipes, or other components. This resistance leads to pressure drops, making the system work harder to maintain airflow and temperature.

The result? Higher energy bills, reduced performance, and potential wear and tear on the system. In this blog, we’ll explore the concept of friction loss, its impacts on HVAC systems, and practical ways to minimize it. Whether you’re a homeowner or a business owner, understanding friction loss can help you optimize your system for better efficiency and comfort.

What is Friction Loss in HVAC?

Friction loss in HVAC refers to the pressure drop that occurs as air or fluids move through ductwork and piping. This happens due to resistance caused by factors like air velocity, surface roughness, duct material, bends, and length of the system. Similar to how water pressure decreases in a long garden hose, friction loss weakens airflow, making it harder for conditioned air to reach its destination.

It increases energy usage, reduces system efficiency, and can shorten component life. Proper duct design, smooth materials, and gradual size transitions help minimize friction loss, ensuring the HVAC system runs effectively and efficiently.

A Clear Definition of Friction Loss in HVAC Systems.

Friction loss in HVAC systems is similar to the resistance your car experiences when driving uphill. Air and fluids in ducts and pipes face challenges as they navigate corners, narrow spaces, and uneven surfaces. Friction loss refers to the pressure drop that occurs as air or fluids flow through the intricate pathways of ductwork and piping.

To measure friction loss, technicians rely on tools like manometers, which detect pressure drops over a specific duct or pipe length. For air ducts, this drop is measured in inches of the water column, while for pipes, it’s recorded in psi. Picture a U-shaped manometer filled with water: as pressure decreases, the water column lowers much like how the water level in a reservoir drops when faucets are opened. Engineers use both hardware tools and software to calculate and account for friction loss.

HVAC Friction Loss is Influenced By Five Main Factors

Understanding what is friction loss in HVAC starts with recognizing the key factors that impact it. These include air velocity, duct or pipe material, length, number of bends, and transition sizes. Each of these elements contributes to how efficiently air or fluids flow through the system. By minimizing resistance in these areas, HVAC systems can operate more effectively, ensuring better performance and energy savings.

- Air Velocity: Faster-moving air or fluids experience higher friction loss than slower flows.

- Duct or Pipe Material: Materials like fiberglass create more resistance than smoother surfaces, such as seamless aluminum or steel.

- Length: Longer duct or pipe runs result in greater friction loss compared to shorter, more direct paths.

- Number of Bends: Sharp 90-degree bends increase friction loss significantly, while multiple 45-degree bends are less restrictive.

- Transition Sizes: Abrupt changes in size, like going from a wide duct to a smaller one, create more friction. Gradual transitions reduce resistance and improve flow efficiency.

Consider an HVAC system supplying air to a large building. If the ductwork is too small or has a rough texture, like sandpaper, the air struggles to move through it. This resistance leads to a significant pressure drop, similar to how a long garden hose loses water pressure when connected to a sprinkler.

The farther the air travels from the fan or air handler, the weaker the airflow becomes. The result? Poor circulation in distant rooms, uneven temperatures, and an overworked HVAC system struggling to maintain the desired comfort levels.

Effects of Friction Loss on HVAC Performance

To understand what is friction loss in HVAC, it’s crucial to know its impact on system performance. Friction loss leads to higher energy consumption, reduced airflow, and uneven temperature distribution. Over time, it strains components like fans and air handlers, shortening their lifespan and increasing maintenance costs. Addressing these effects through proper system design and maintenance ensures better efficiency and longer system life.

Higher Energy Consumption

When friction loss increases in an HVAC system, the system has to work harder to maintain airflow and temperature. This extra effort demands more energy, leading to higher utility bills. Over time, the energy inefficiency caused by friction loss can significantly increase operational costs, making it essential to design systems with minimal resistance to reduce energy consumption and ensure long-term savings.

Decreased System Efficiency

Friction loss disrupts the smooth flow of air, reducing the overall efficiency of your HVAC system. As airflow weakens, rooms may not receive adequate cooling or heating, causing uneven temperature distribution. The system struggles to meet demand, lowering performance and increasing wear and tear. By addressing friction loss, you can restore efficiency and ensure consistent comfort throughout your space.

Reduced Lifespan of Components

Excessive friction loss puts additional strain on key HVAC components, like fans and air handlers. Over time, this stress accelerates wear and tear, shortening their lifespan and leading to more frequent repairs or replacements. Proper system design, routine maintenance, and minimizing resistance can help protect components, ensuring your HVAC system runs smoothly and lasts longer.

Ways to Reduce Friction Loss in HVAC Systems

Knowing what is friction loss in HVAC is the first step to addressing it effectively. Reducing friction loss involves designing efficient ductwork, using smooth, high-quality materials, and ensuring proper system balance. Regular maintenance also plays a critical role in keeping airflow unobstructed. By taking these measures, you can enhance system efficiency, lower energy consumption, and extend the lifespan of your HVAC components.

Designing Efficient Ductwork

A well-designed duct system plays a crucial role in reducing friction loss.

- Use of Larger Ducts: Larger ducts allow air to move more freely, reducing airflow resistance and pressure drops. This improves efficiency and overall system performance.

- Proper Placement of Bends and Transitions: Sharp bends and abrupt transitions create turbulence and increase resistance. Gradual turns and smooth transitions minimize friction, enabling smoother airflow throughout the system.

Using Durable, High-Quality Materials

Choosing the right materials for ducts and piping is essential to minimize friction loss.

- Benefits of Smooth Materials: Ducts with smooth inner surfaces, like sheet metal or advanced polymers, significantly reduce friction and enhance airflow.

- Insulated Ductwork: Insulated ducts help maintain consistent temperatures, reducing the need for additional airflow to compensate for fluctuations. This lowers the strain on the system and improves efficiency.

Performing Routine Maintenance

Routine maintenance ensures the system operates efficiently and avoids unnecessary friction.

- Cleaning Ducts to Avoid Blockages: Dust, debris, and other contaminants can accumulate over time, increasing resistance. Regular cleaning keeps airflow unobstructed and maintains system performance.

- Inspecting and Repairing Leaks: Leaks in ductwork cause air to escape, forcing the system to work harder. Regular inspections and prompt repairs keep the system sealed and efficient.

Balancing the System

Proper airflow management ensures the HVAC system operates evenly and efficiently.

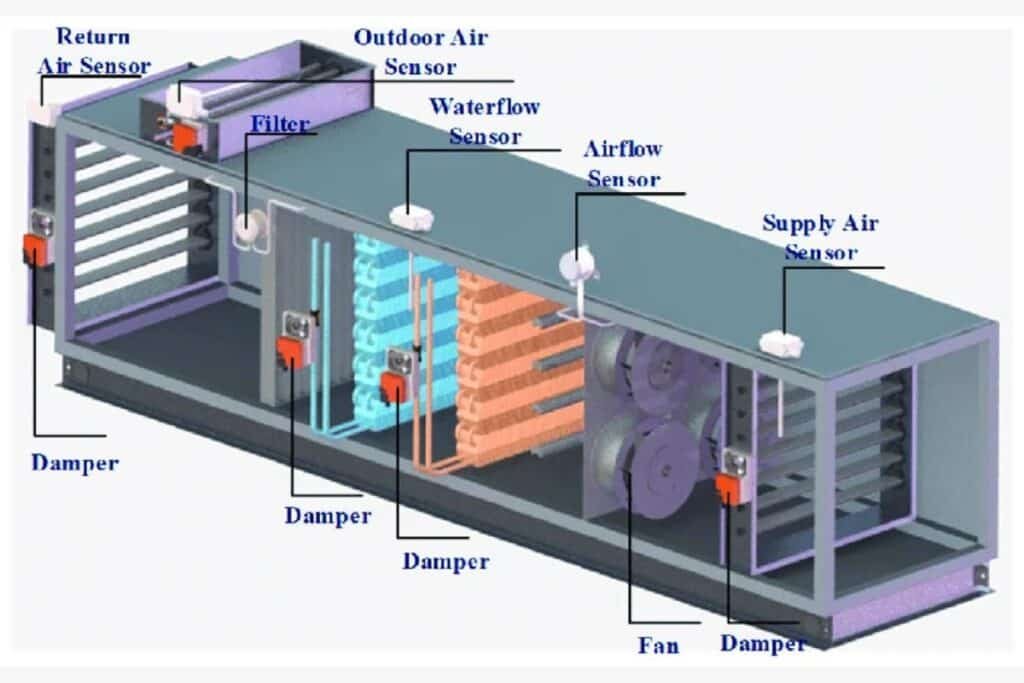

- Using Dampers Effectively: Dampers control airflow to different zones, ensuring balanced distribution and preventing the system from overworking in specific areas.

- Employing Professional Design and Testing: Engaging experienced HVAC professionals to design, install, and test the system ensures peak efficiency with minimal friction loss. Additionally, addressing poor insulation can further enhance system performance and efficiency.

How HVAC Engineers Address Friction Loss During System Design

Engineers design HVAC systems with friction loss in mind, integrating strategies during the planning phase to minimize its impact and maintain efficiency.

A key tool in this process is the Darcy-Weisbach equation, which calculates velocity pressure loss caused by friction in ducts or pipes. This formula considers factors such as flow velocity, duct roughness, and length to provide accurate measurements. By applying these calculations, engineers can optimize duct sizes and materials to reduce resistance.

In addition to mathematical models, engineers adhere to ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) standards. These guidelines outline best practices for duct sizing, airflow rates, and material specifications, helping engineers design systems that minimize friction loss while maximizing energy efficiency. By following these recommendations, designs meet industry benchmarks and deliver reliable performance.

Striking a balance between efficiency and cost is also essential. Larger ducts or straight pipes reduce friction loss but involve higher material and installation costs. Engineers evaluate these trade-offs to determine where long-term energy savings outweigh initial expenses. Similarly, smoother, high-quality materials lower resistance but must fit within budget constraints. To make informed decisions, engineers often use energy modeling software to simulate various designs, identifying cost-effective solutions that optimize efficiency and performance.

Achieving Optimal Airflow Without Sacrificing Energy Efficiency

Friction loss in HVAC systems isn’t just a technical detail—it’s a key factor influencing energy consumption, performance, and long-term costs. So, what is friction loss in HVAC? It’s the resistance air or fluids face as they travel through ducts, pipes, or system components.

By focusing on efficient design, high-quality materials, and routine maintenance, homeowners and businesses can enhance comfort and reduce expenses. Minimizing friction loss ensures HVAC systems operate efficiently, last longer, and deliver consistent, reliable performance. Proactive measures make a noticeable difference in both energy savings and system longevity.

Contact With Big Apple Air HVAC Contractor in New York City

Big Apple Air is a leading HVAC contractor in New York City, specializing in heating, ventilation, and air conditioning services for both residential and commercial clients. Their certified technicians offer a comprehensive range of services, including HVAC installation, maintenance, replacement, and repair, all aimed at enhancing indoor comfort. Clients commend Big Apple Air for their expertise in heating and cooling solutions, ensuring optimal indoor conditions throughout the year.

We pride ourselves on delivering quality, efficiency, and customer satisfaction, making them a preferred choice for HVAC services in New York. For inquiries or to request a free estimate, you can contact us at +1 347 873 6190

To Wrap Up

What is Friction Loss in HVAC? It’s a critical factor that directly affects the efficiency, performance, and longevity of your system. By understanding how friction loss impacts airflow and energy use, you can take proactive steps to reduce resistance within your HVAC system. From well-designed ductwork and high-quality materials to regular maintenance and professional assessments, minimizing friction loss ensures better energy efficiency, lower operational costs, and consistent comfort.

Whether you’re upgrading your system or maintaining an existing one, addressing friction loss is essential for optimal performance. With the right approach, you can enhance the reliability and lifespan of your HVAC system while keeping your energy expenses in check.